's definition of high open area perforating is as follows:

's definition of high open area perforating is as follows:

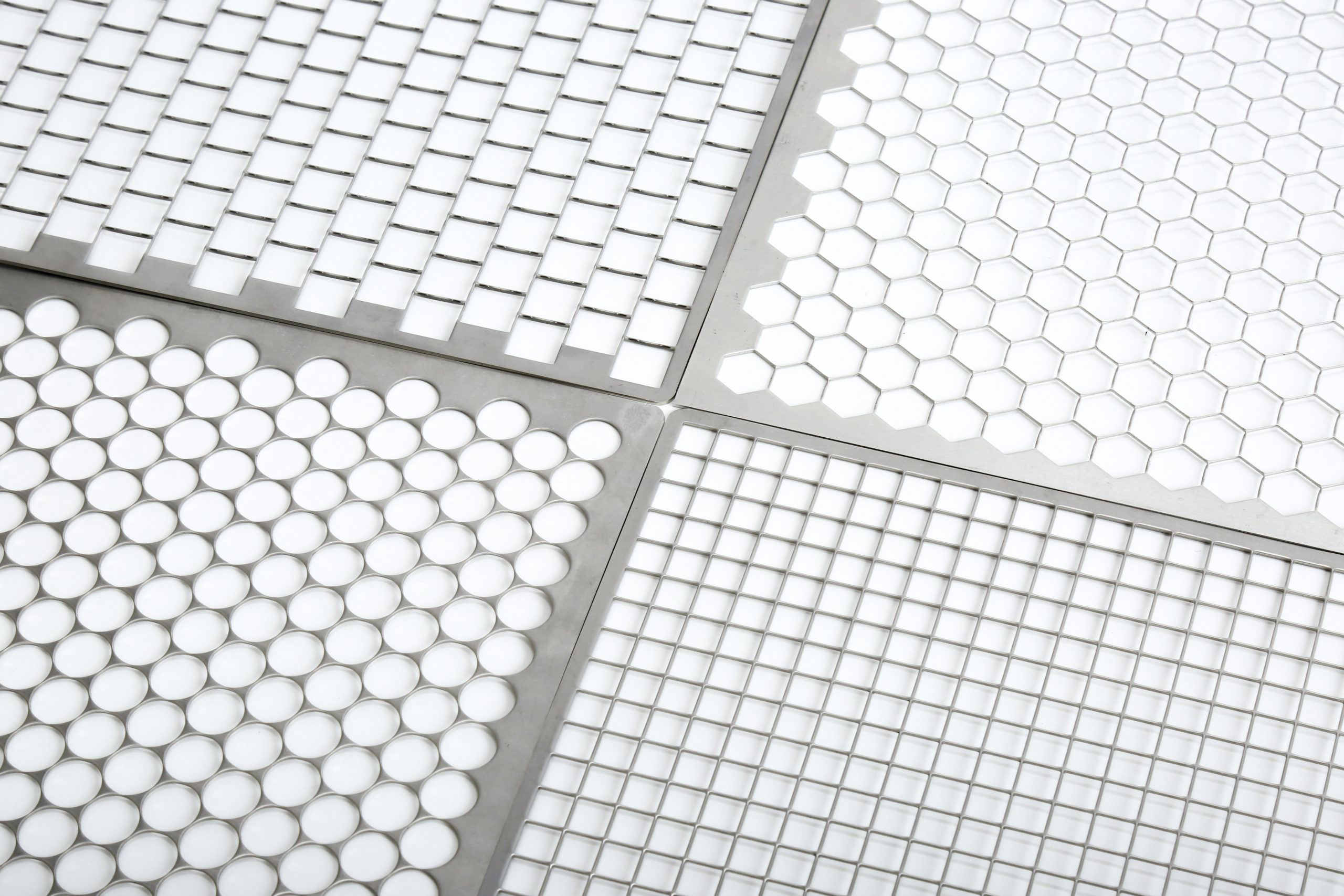

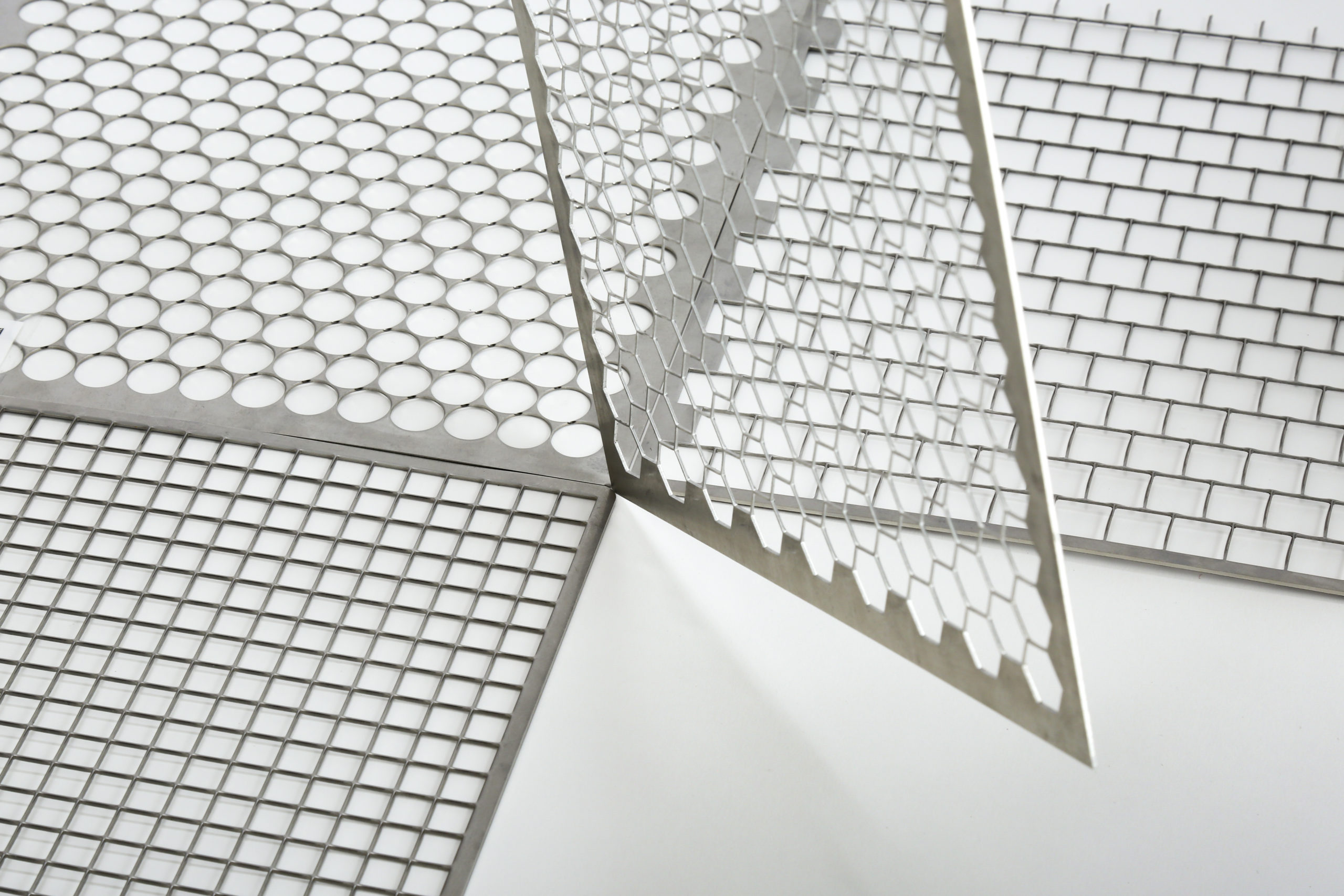

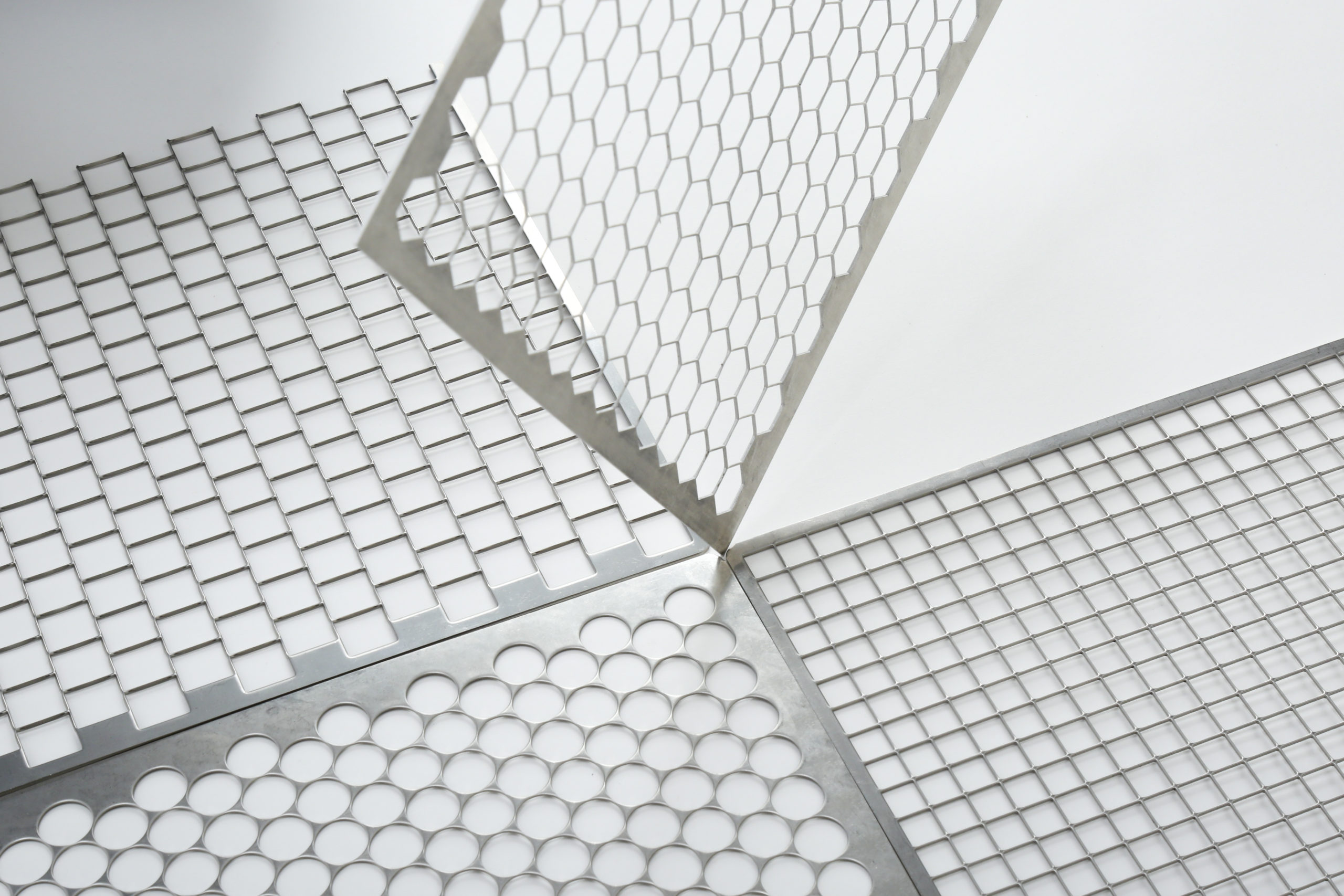

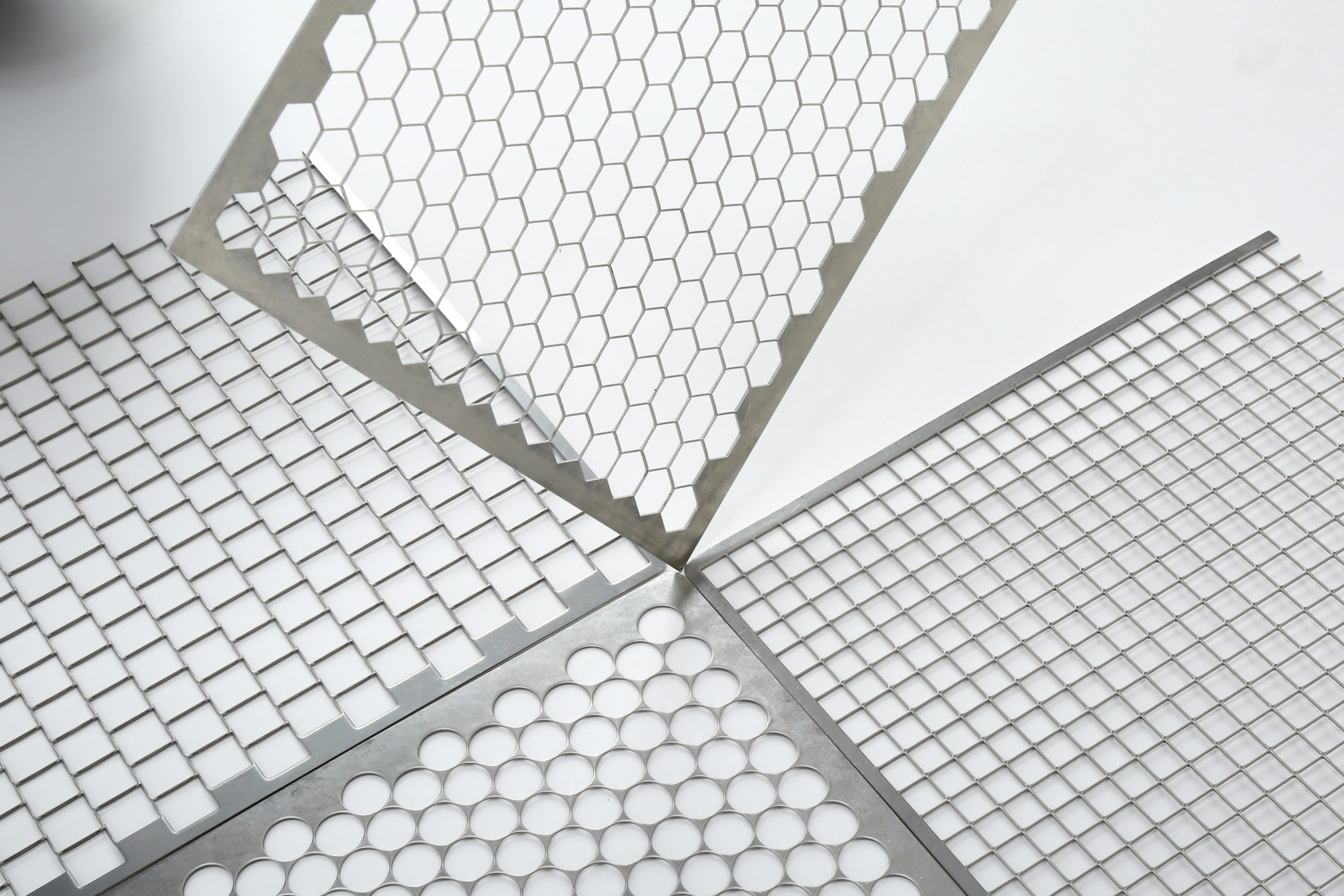

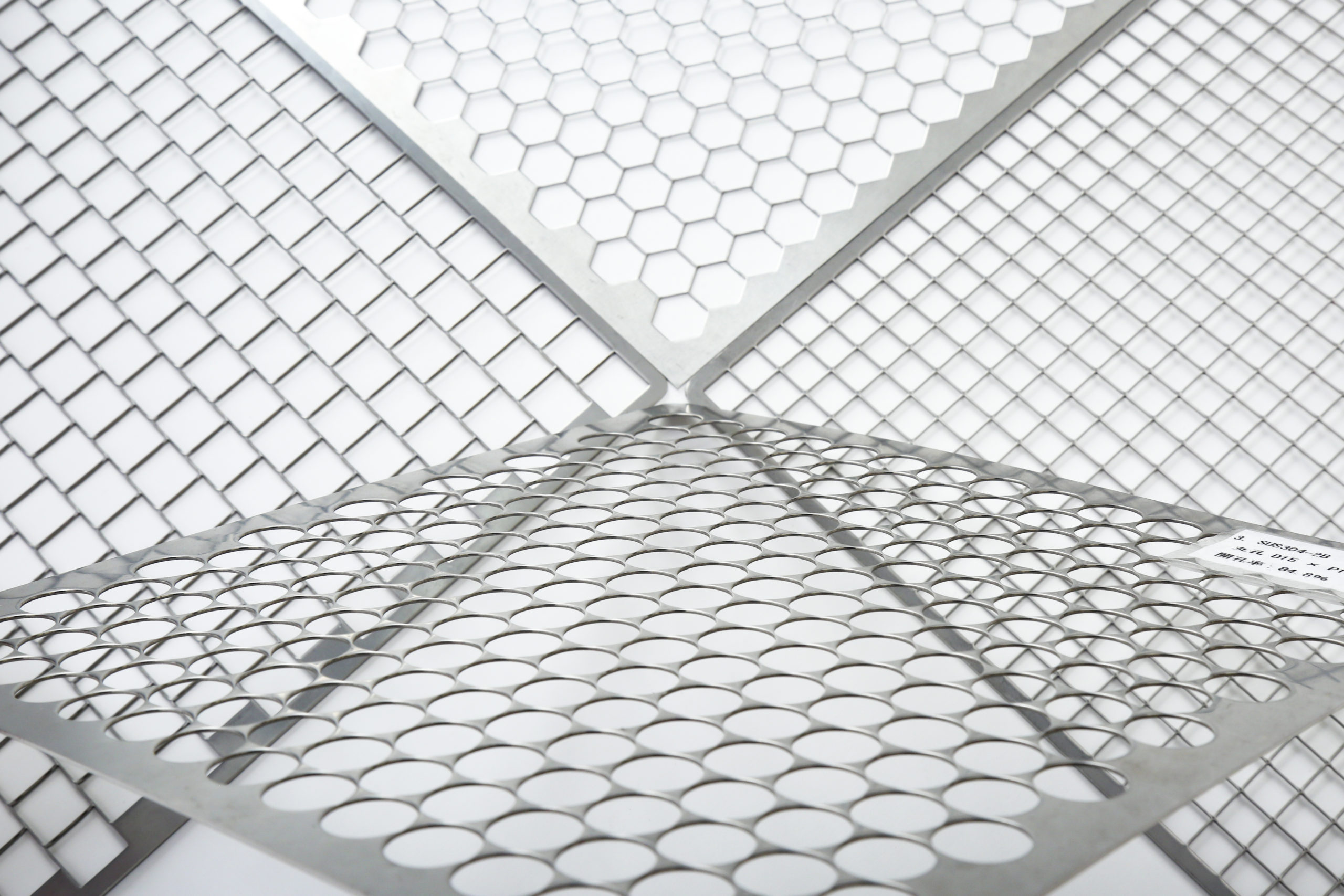

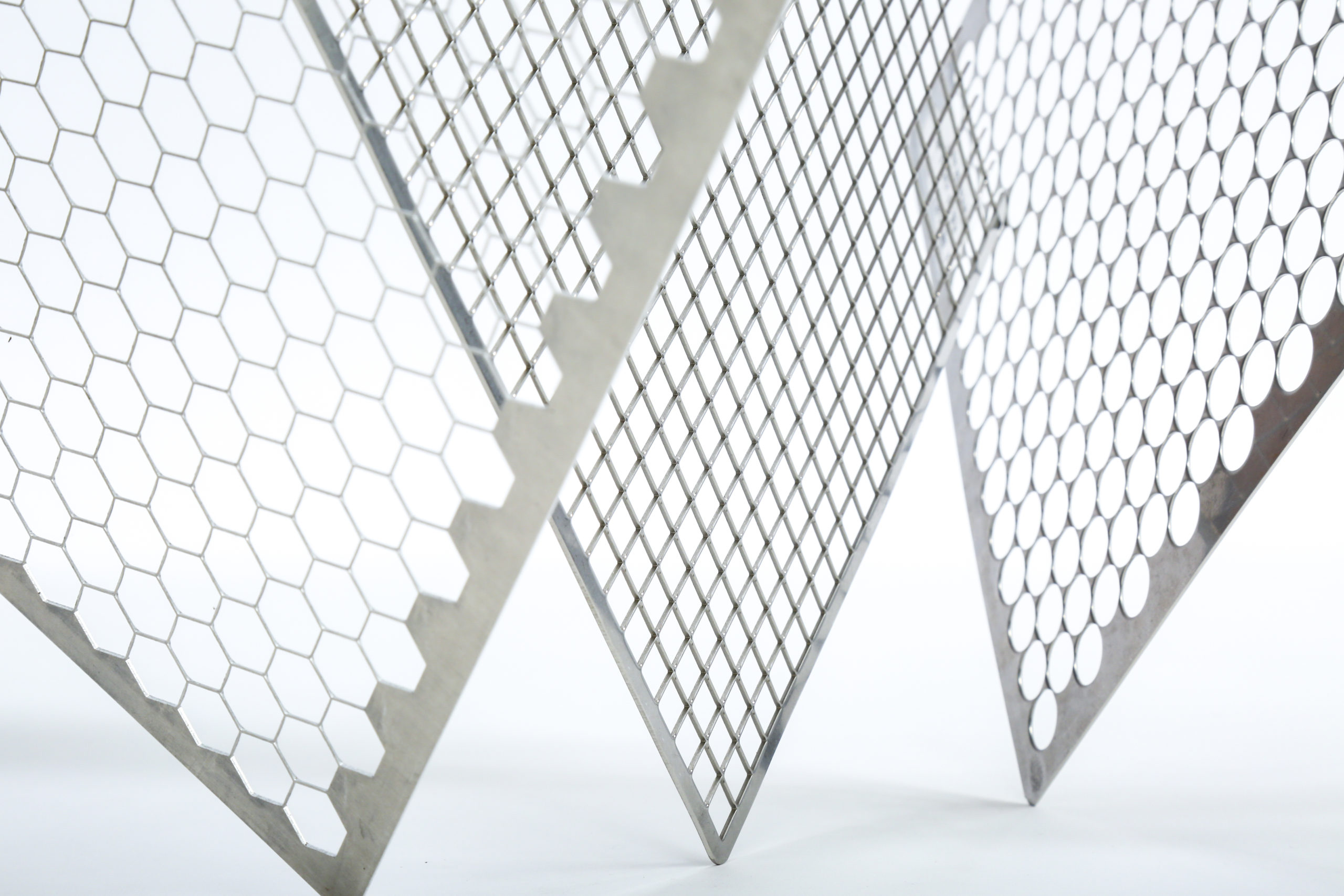

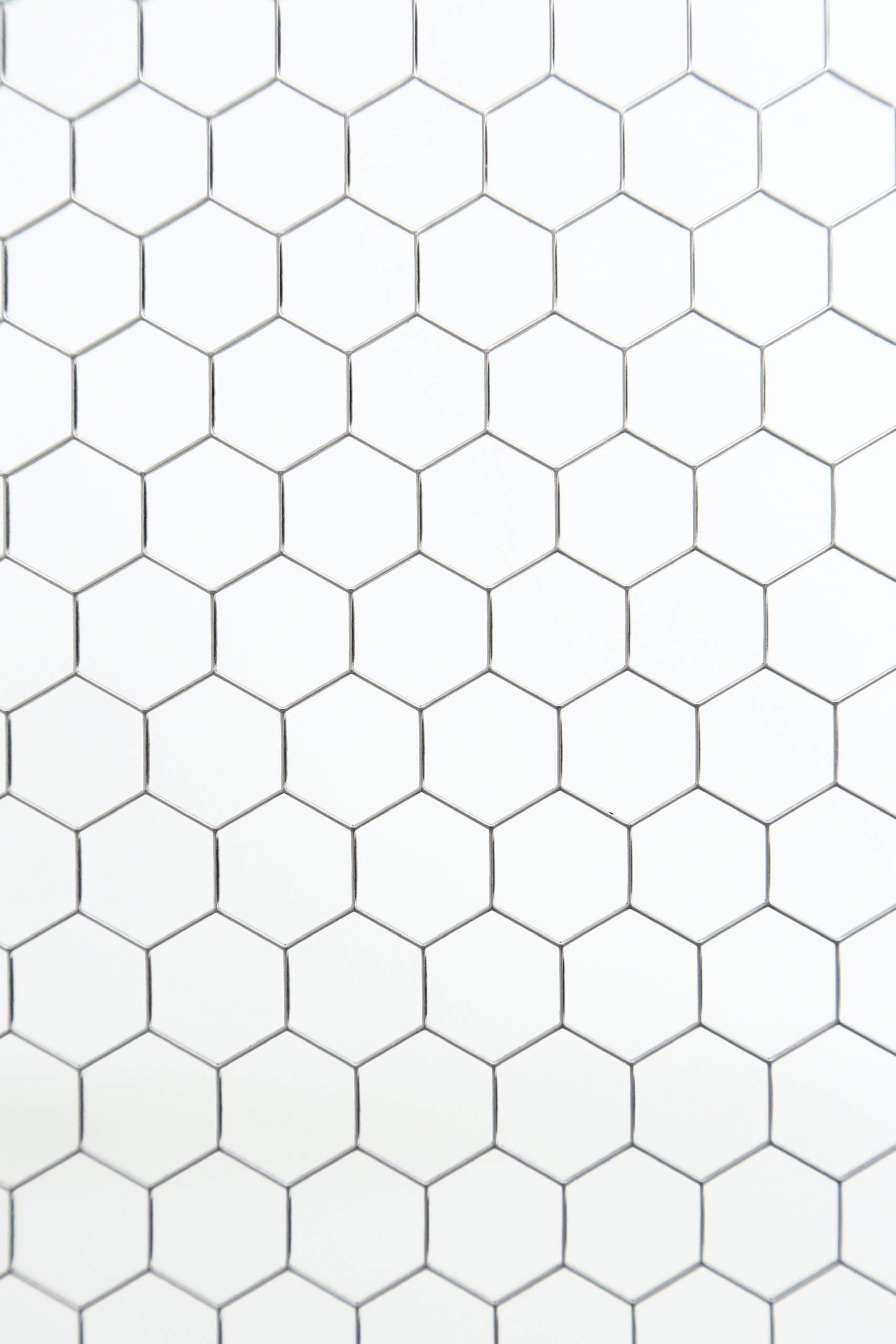

| Hexagonal hole |  |

Over 80% |

|---|---|---|

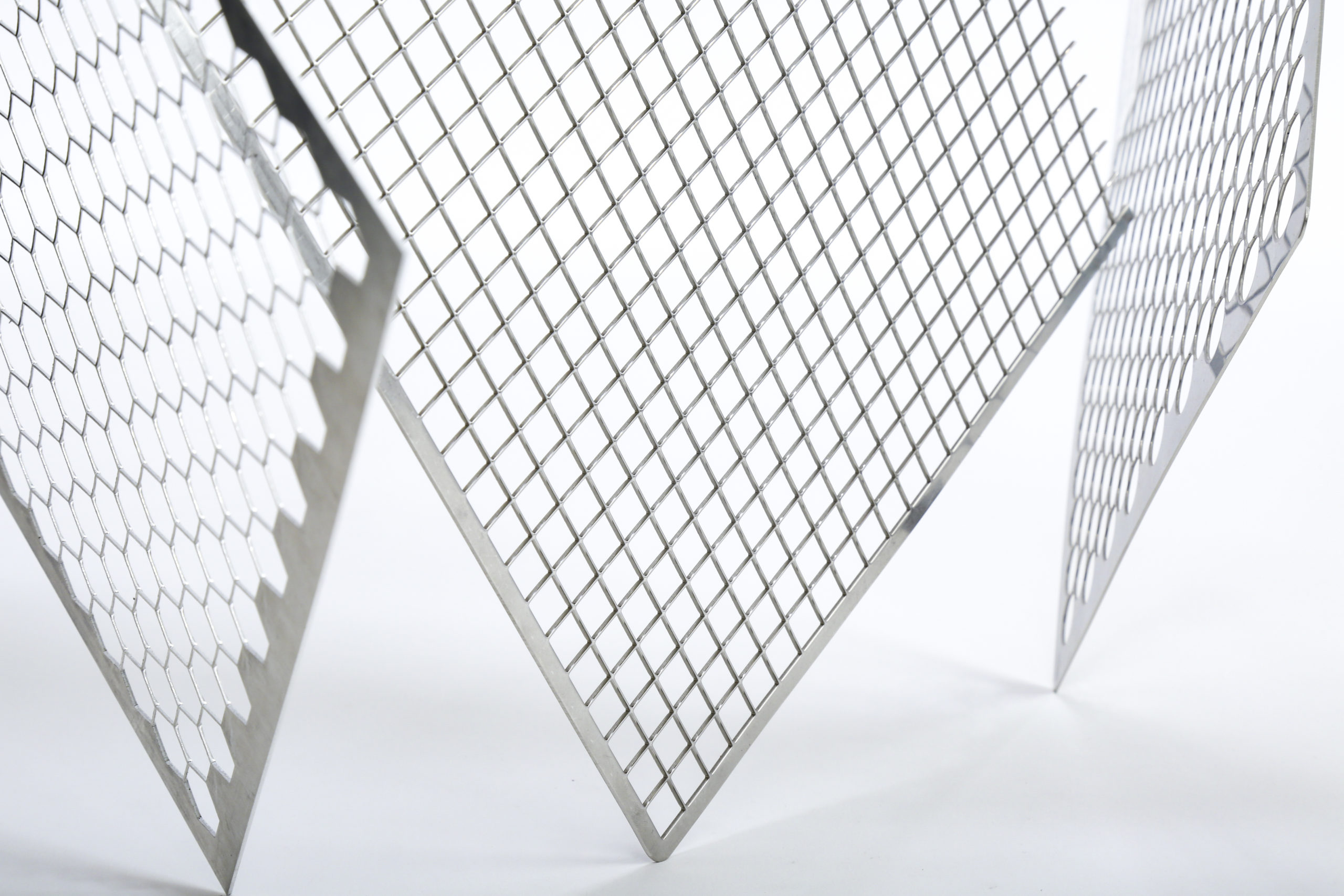

| Square hole |  |

Over 80% |

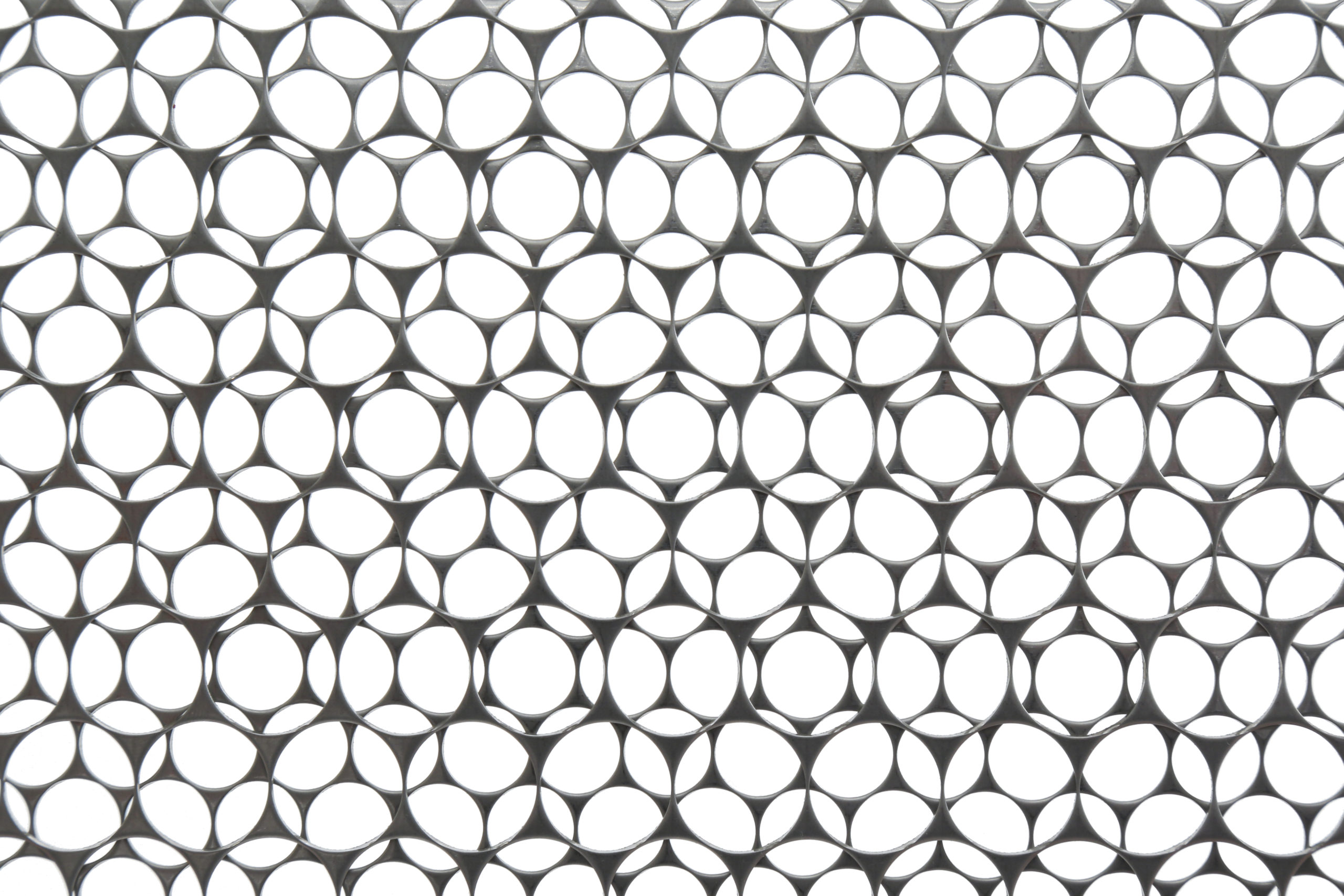

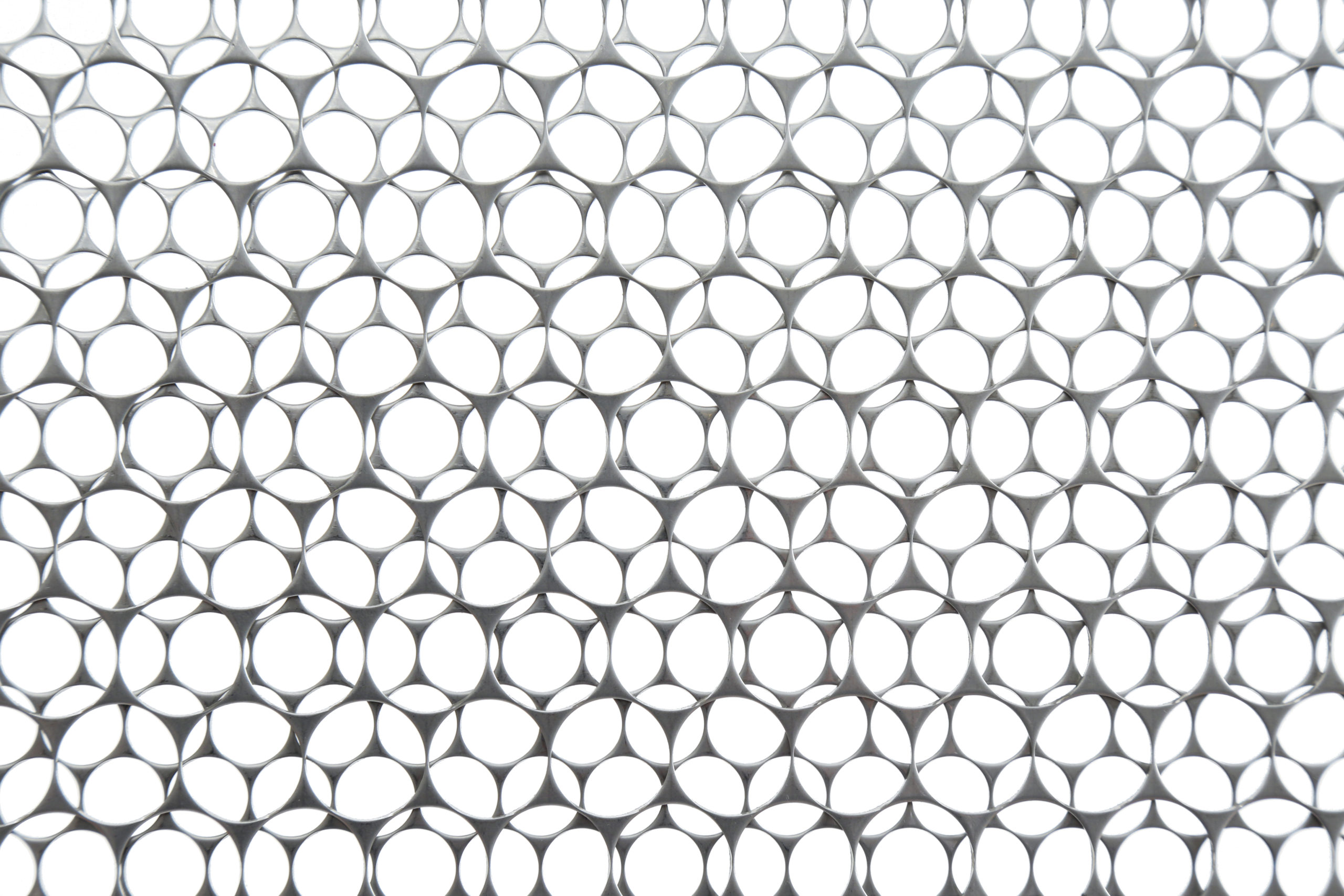

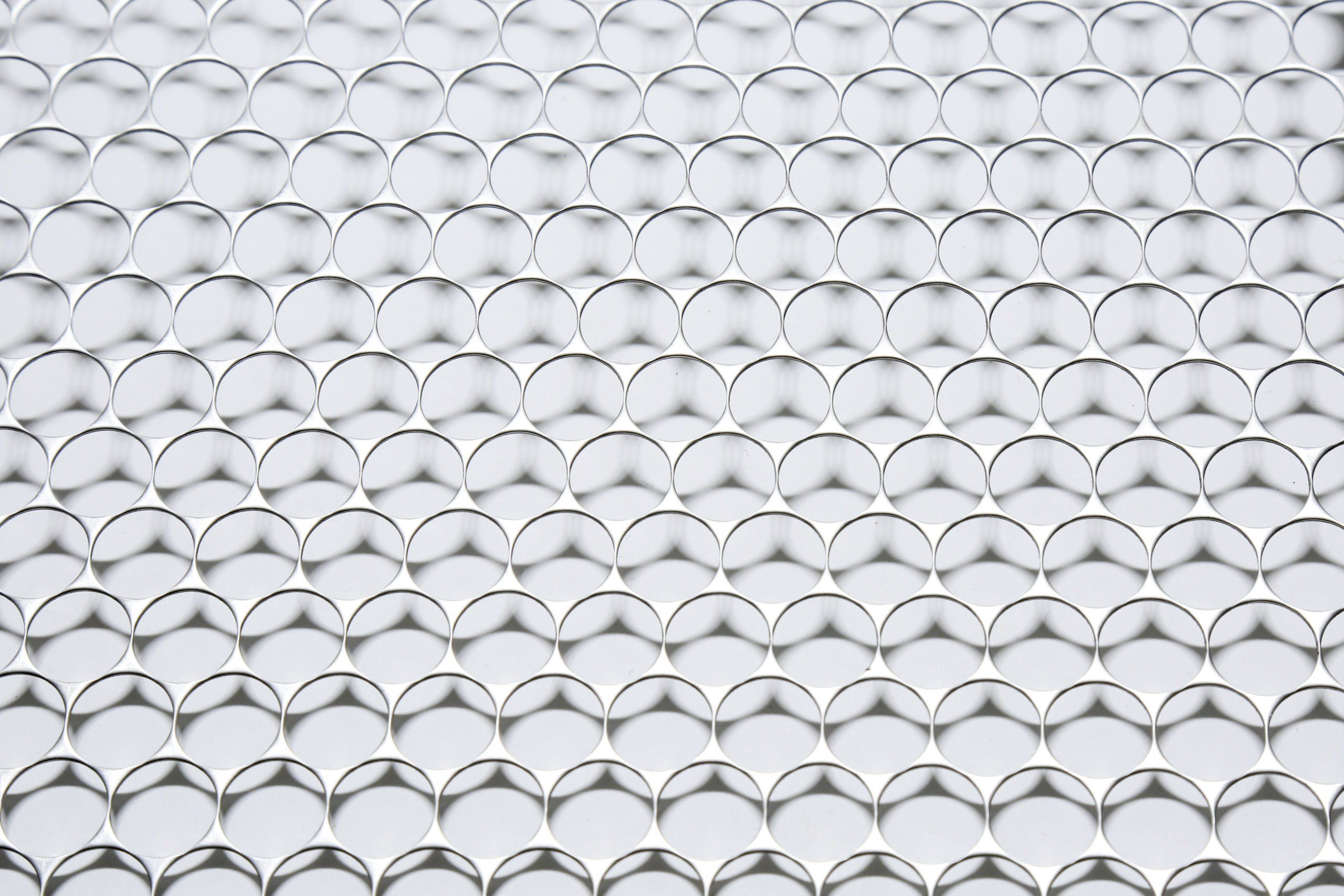

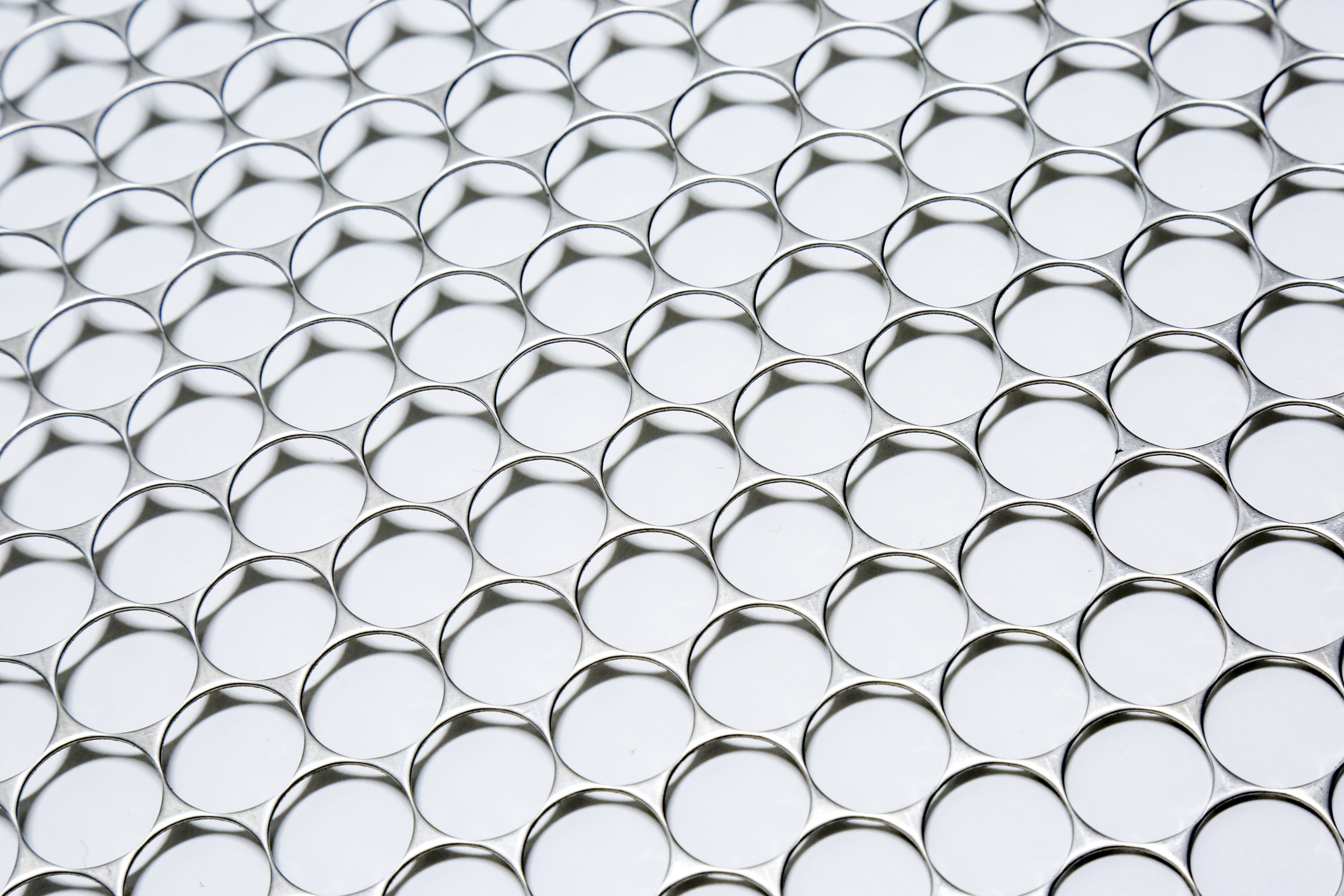

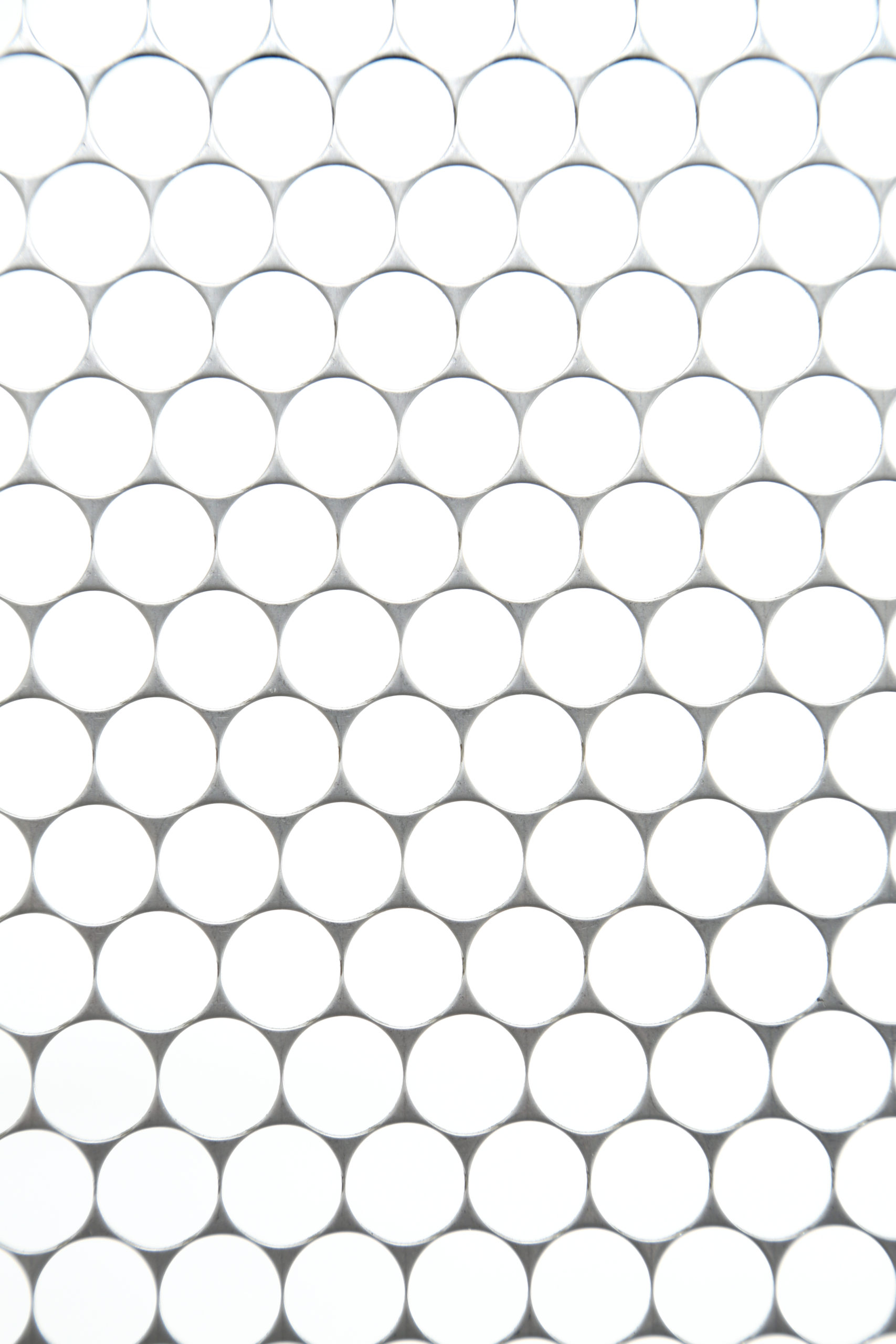

| Round hole |  |

Up to φ6mm : over 70% Equal to or higher than φ8mm : over 75% |

|

|

|

|

|

|

|

|

|

|

|

| ・Air filters | ・Housing (reinforcing materials) |

| ・Protecting cover | ・Speaker cover |

| ・Interior and exterior design materials | ・Ventilating facilities |

| ・Heat dissipation |

| ・Stainless Steel | ・Aluminum |

| ・Mild steel |

| Catalog No. | Hole shape | Hole size | Pitch | Pattern | Open area | Max. sheet size | Enlarged Photo |

|---|---|---|---|---|---|---|---|

| X4111 | Hexagon | W5 | 5.5 | 60 degree staggered |

82.60% | 500×500 | Photo |

| X4113 | W10 | 10.5 | 90.70% | 500×1000 | Photo | ||

| X4115 | W15 | 15.5 | 93.70% | 500×1000 | Photo | ||

| X4261 | Square | 5×5 | 5.5 | Straight | 82.60% | 500×500 | Photo |

| X4263 | 10×10 | 10.5 | 90.70% | 500×1000 | Photo | ||

| X4265 | 15×15 | 15.5 | 93.70% | 500×1000 | Photo | ||

| X4281 | Square | 5×5 | 5.5 | Staggered | 82.60% | 500×500 | Photo |

| X4283 | 10×10 | 10.5 | 90.70% | 500×1000 | Photo | ||

| X4285 | 15×15 | 15.5 | 93.70% | 500×1000 | Photo | ||

| X4311 | Round | Φ5 | 5.5 | 60 degree Staggered |

74.90% | 500×500 | Photo |

| X4313 | Φ10 | 10.5 | 82.20% | 500×1000 | Photo | ||

| X4315 | Φ15 | 15.5 | 84.80% | 1000×1000 | Photo |

| Catalog No. | Hole shape | Hole size | Pitch | Pattern | Open area | Max. sheet size | Enlarged Photo |

|---|---|---|---|---|---|---|---|

| X4141 | Hexagon | W6 | 6.7 | 60 degree staggered |

80.20% | 500×1000 | Photo |

| X4144 | W10 | 10.75 | 86.50% | 1000×1000 | Photo | ||

| X4143 | W10 | 10.5 | 90.70% | 1000×1000 | Photo | ||

| X4145 | W15 | 15.75 | 90.70% | 1000×1000 | Photo | ||

| X4271 | Square | 6×6 | 6.7 | Straight | 80.20% | 500×1000 | Photo |

| X4273 | 10×10 | 10.75 | 86.50% | 1000×1000 | Photo | ||

| X4275 | 15×15 | 15.75 | 90.70% | 1000×1000 | Photo | ||

| X4291 | Square | 6×6 | 6.7 | Staggered | 80.20% | 500×1000 | Photo |

| X4293 | 10×10 | 10.75 | 86.50% | 1000×1000 | Photo | ||

| X4295 | 15×15 | 15.75 | 90.70% | 1000×1000 | Photo | ||

| X4343 | Round | Φ5 | 5.75 | 60 degree Staggered |

68.50% | 500×500 | Photo |

| X4342 | Φ5 | 5.6 | 72.2% | 500×1000 | Photo | ||

| X4341 | Φ5 | 5.5 | 74.90% | 1000×1000 | Photo | ||

| X4346 | Φ10 | 10.75 | 78.40% | 1000×1000 | Photo | ||

| X4345 | Φ10 | 10.5 | 82.20% | 1000×1000 | Photo | ||

| X4348 | Φ15 | 15.75 | 82.20% | 1000×1000 | Photo |

| Catalog No. | Hole shape | Hole size | Pitch | Pattern | Open area | Max. sheet size |

|---|---|---|---|---|---|---|

| X4101 | Hexagon | W5 | 5.5 | 60 degree staggered |

82.60% | 500×1000 |

| X4103 | W10 | 10.5 | 90.70% | 500×1000 | ||

| X4105 | W15 | 15.5 | 93.70% | 500×1000 |

| Catalog No. | Hole shape | Hole size | Pitch | Pattern | Open area | Max. sheet size |

|---|---|---|---|---|---|---|

| X4131 | Hexagon | W5 | 5.5 | 60 degree staggered |

82.6% | 500×1000 |

| X4133 | W10 | 10.5 | 90.7% | 500×1000 | ||

| X4135 | W15 | 15.5 | 93.7% | 500×1000 |

| Catalog No. | Hole shape | Hole size | Pitch | Pattern | Open area | Max. sheet size | Enlarged Photo |

|---|---|---|---|---|---|---|---|

| X4122 | Hexagon | W5 | 6 | 60 degree staggered |

69.40% | 1000×1000 | Photo |

| X4114 | W10 | 11 | 82.60% | 1000×1000 | Photo | ||

| X4116 | W15 | 16 | 87.90% | 1000×1000 | Photo | ||

| X4262 | Square | W5 | 6 | Straight | 69.40% | 1000×1000 | Photo |

| X4264 | W10 | 11 | 82.60% | 1000×1000 | Photo | ||

| X4264 | W15 | 16 | 87.90% | 1000×1000 | Photo |

*No margin in principal. To be discussed separately in case of needing margins. (under the limited condition)

*The distortion would be remained due to too narrow pitch, so the dimensional tolerances can’t be defined.

![]() Click on the picture to go to the product image page.

Click on the picture to go to the product image page.

|

|

|

| X-Open area Round hole | X-Open area Square | X-Open area Hexagon |