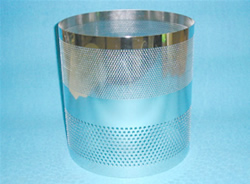

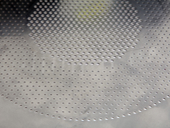

Perforated metal is a metal sheet that is punchedAluminum and Anodized Aluminum with holes in a uniform pattern.

It is used in many fields.

Machinery covers, ornamental covers, speaker grills, storage, radiator grills, stove grills, protecting covers

Click HERE to see examples.

Air filters, oil filters, mufflers, front grills, interior and exterior parts

Click HERE to see examples.

Heat insulation panels, noise insulation panels for construction sites, vehicles and vessels

Click HERE to see examples.

Wall paneling, partitioning, ornamentals, lighting equipment, exterior panels, fixtures, chairs, tables, ceilings

Click HERE to see examples.

For production of sugar, pulp and paper,flour, oil refining, distillation columns

Click HERE to see examples.

Boilers, ventilators, kitchen furniture, planters, shields for microwave ovens, dust boxes

Click HERE to see examples.

For screening grains, seeds, coal, sands, gravels and chemical products

Click HERE to see examples.

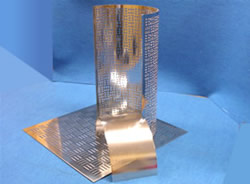

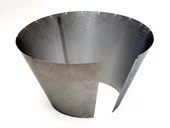

For production of granular and tablet pharmaceuticals, cube sugar, instant coffee, agricultural chemicals, fertilizers, chemical products

Used for granulating solid materials to specific size and shape desired in particular applications.

Applications

Production of granular and tablet pharmaceuticals, cube sugar, instant coffee, agricultural chemicals, fertilizers, chemical products, etc.

Used in machines for physically crushing and milling solid materials.

Manufacture of drugs, agricultural chemicals, fertilizers, industrial chemicals, etc.

Perforated metals for granulators and mills are produced from materials and with plate thicknesses and hole sized suitable to particular applications.

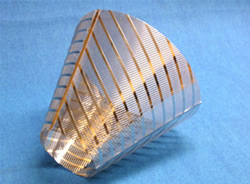

For food, chemicals, pharmaceuticals, pulp and paper, mining and ceramic industries

Used for separating crystals from a filtrate in chemical industry.

Production process in food, chemicals, paper making, pharmaceuticals, mining, and ceramic industries as well as sewage treatment, waste treatment and industrial waste water treatment.

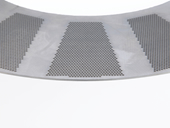

Sectorial or conical shapes can be formed upon request.

Please contact for more information.

Please make full use of our fabrication services.

*In the case of sieves, please specify direction the of flow of object to be sifted, because the through-put might be increased depending on the feed direction.

<Example>

D=10 P=15 60 deg. staggered

Please specify the orientation of slots in relation to the width and length of perforated metal sheet.

| Standard | Step-and-a-half | Two-steps-and-a-half | ||

Feed direction |

|

|

|

|

|

|

|

||

| Standard layout: The pattern at the beginning and end of the sheet is complete, providing the finished ends. | Optional layouts: When it is difficult to use the standard layout due to a hole size in relation to a plate thickness and/or a pitch required, such optional layout as a step-and-a-half and two-steps-and-a-half layouts is used. In such case, the pattern of holes at the beginning and end of the sheet is incomplete, as shown above, providing unfinished ends. | |||

Standard layout |

Step-and-a-half layout |

|

|

|

As shown above, a perforating die layout for a staggered formation includes an even number of rows of punches in a die. The patterns at the beginning and end of the sheet are asymmetric.

|

For zone perforation, please specify A or B below. |

|

|

|

|

A: Distance between the top end of the first hole and the bottom end of the last hole |

Perforation processing is available only in specified zones as illustrated above. (The finished metal sheet may be slightly strained.) |

|

Four-row die layout |

Two-row die layout |

|

|

|

Steps of die width are caused in slant and circular processing as illustrated above. (Steps are less noticeable in the case of single-row die layout.) |

|

With side and end margins |

Without margins |

|

|

|

|

A: Distance between the end of the sheet and end of the nearest hole |

|

|

All products have an excellent flatness, because they are subjected to corrective roll leveling after perforating process. Due to reaction of the forces accumulated in the perforated metal sheets during processing, the sheets may be slightly strained.

This should be noted especially in the following cases:

A Margins are wide.

B A blank area is present between perforated areas.

C The pitch is low. (The percentage of open area is high.)

D The sheet to be processed is relatively thick.

E The sheet to be processed is very long.

F Stainless steel or a special material is to be processed.

G A margin must be left in a disk-shaped plate.

| ●In the case of cutting from standard size, the final product should have either:

(1) no margin on any sides; or Please let us know if (1) is specifically required. Cutting to a specified size is also available. |

(1) No margin on any sides |

(2) Margin on some sides |

|

|

|

|

|

|

|

|

|

|

Shown above are only examples of various cutting patterns available.

![]() Click to enlarge.* Not shown in full scale.

Click to enlarge.* Not shown in full scale.

![]() Click to enlarge.* Not shown in full scale.

Click to enlarge.* Not shown in full scale.

![]() Click to enlarge.* Not shown in full scale.

Click to enlarge.* Not shown in full scale.

|

|

|

| SUS304 t1.5×Regular Hexagon12× P13 60deg. Staggered |

t2×D7/H1.3×P10 | |

|

|

![]() Click to enlarge.* Not shown in full scale.

Click to enlarge.* Not shown in full scale.

|

Compare finished perimeters.

![]() Click to enlarge.* Not shown in full scale.

Click to enlarge.* Not shown in full scale.

|

|

| Laser Beam Cutting SUS304 0.5t-12t * Please ask for other thicknesses. |

Nibbling SUS304 0.5t-3t |