Released a high-strength sanitary strainer that solves the stainless steel strength problem of screens used in the filtration process during food production and reduces costs!

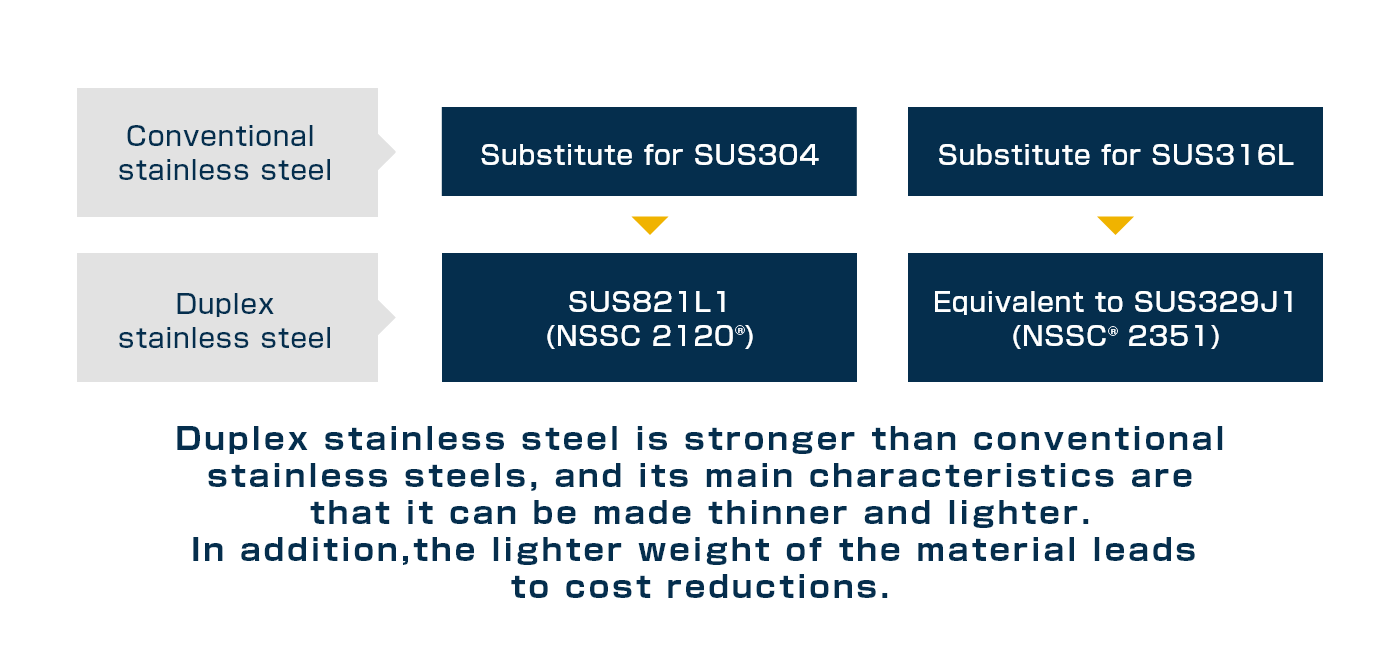

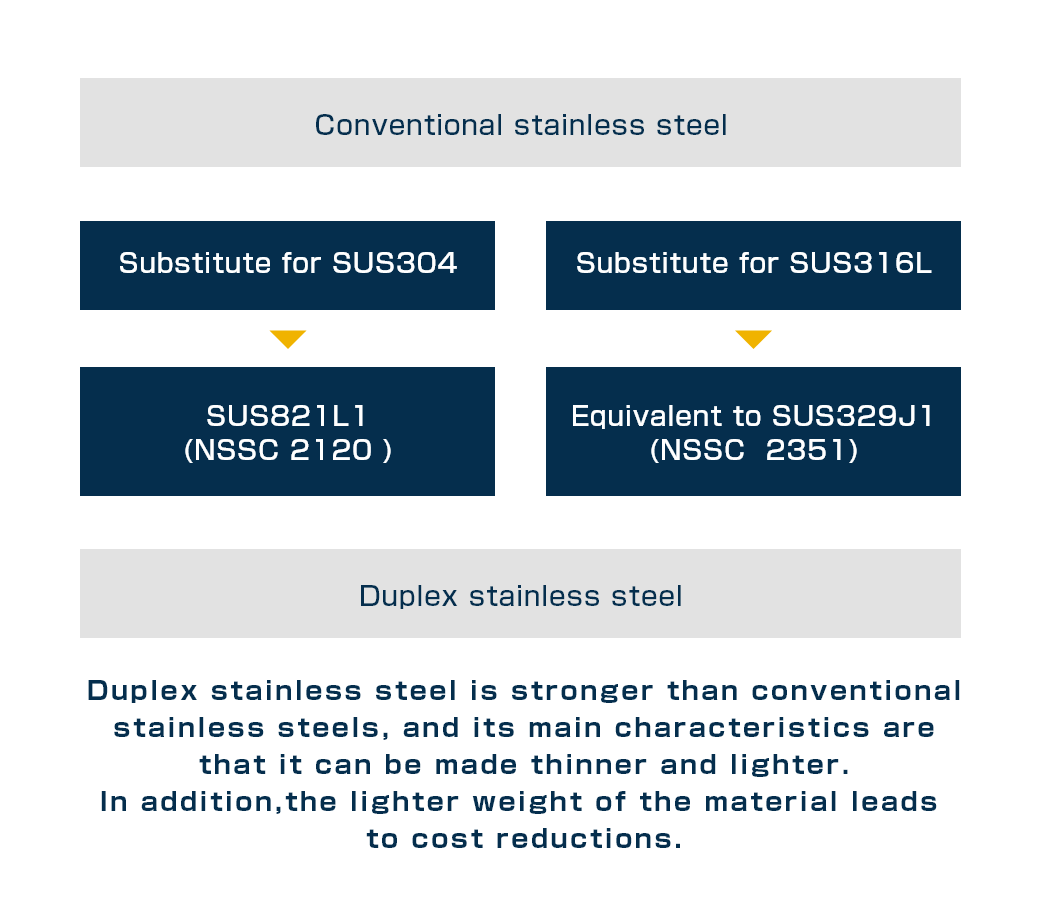

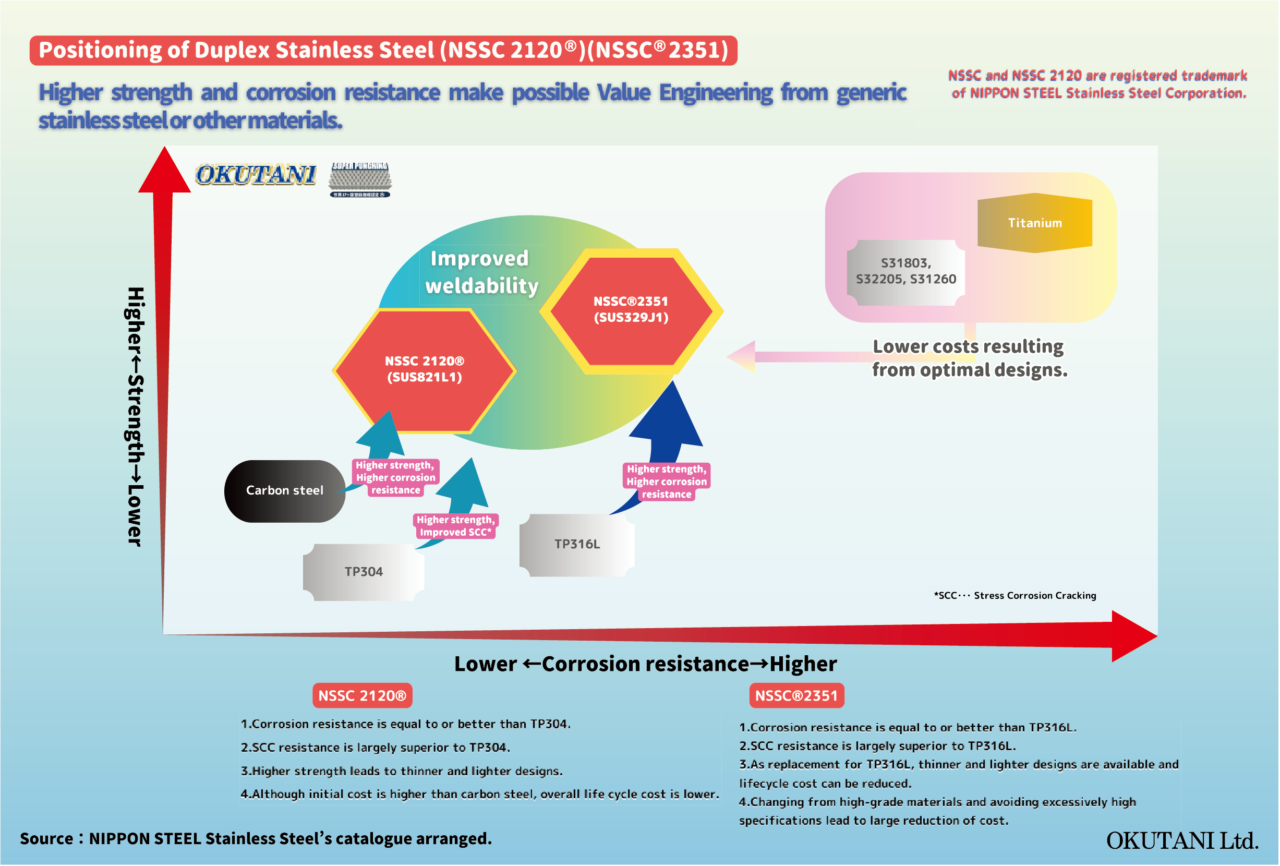

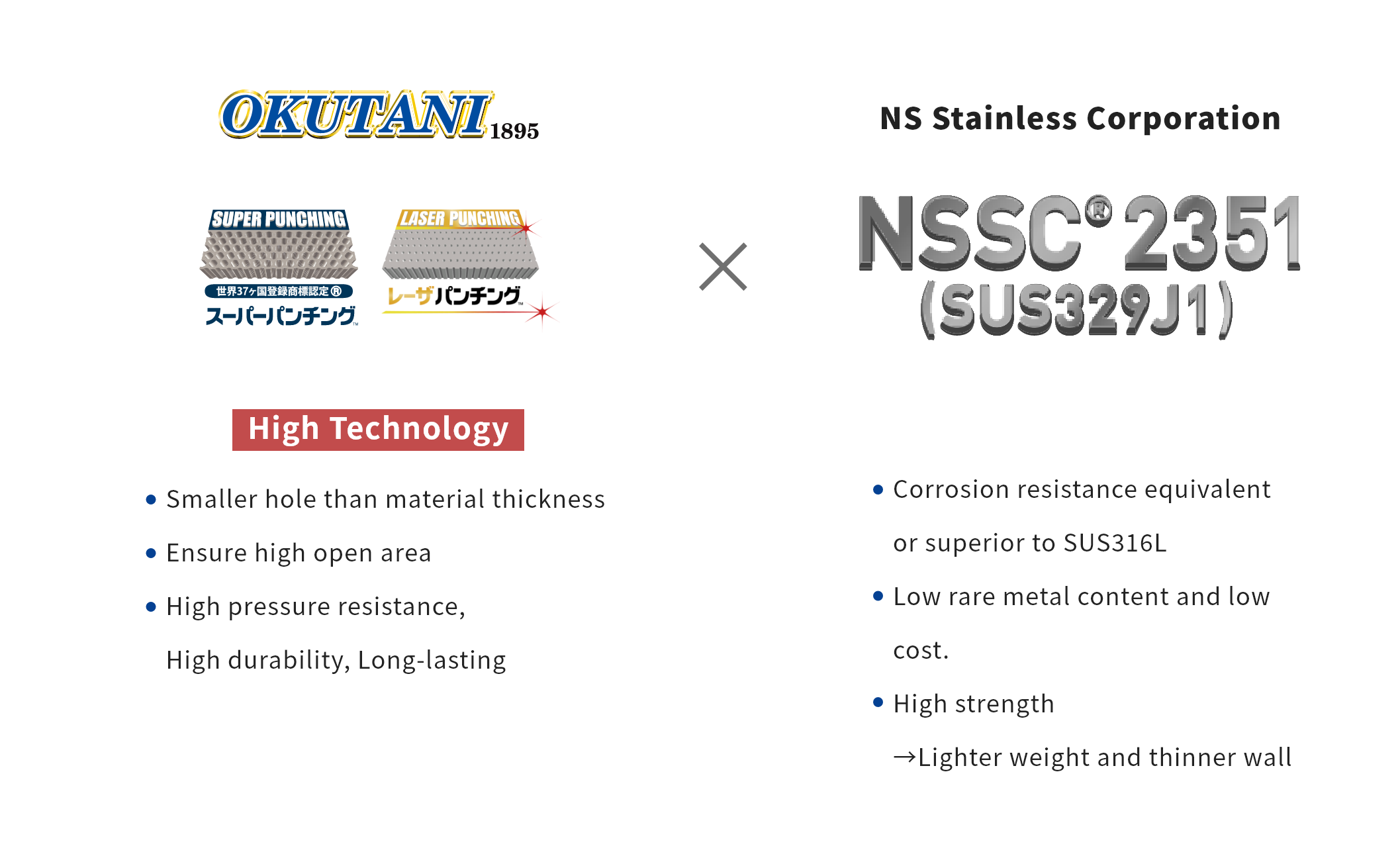

Duplex stainless steel sanitary strainers are made of duplex stainless steel (SUS821L1 (NSSC 2120®), Equivalent to SUS329J1 (NSSC®2351) ) instead of conventional stainless steel (SUS304, SUS316L) provide approx. twice strength and wear resistance, and improve Pitting Resistance Equivalent, and also the price is stable due to its low content of rare metals.

We have experiences to contribute 10 - 30 % of cost reduction by switching to duplex stainless steel.

NSSC,NSSC 2120 are registered of NIPPON STEEL Stainless Steel Corporation.

<NIPPON STEEL Stainless Steel Corporation>https://stainless.nipponsteel.com/news/2022/20220607.php

For problems in the production of food/beverage products and pharmaceuticals

Want to reduce the replacement frequency of equipment used in food factories. |

Want to lower the man-hours required to polish chemicals and pharmaceuticals. |

Want to stabilize costs without price fluctuations. |

Want to use environmentally friendly equipment. |

Changing the strainer material from conventional stainless steel to duplex stainless steel solves all problems!

Replacing sanitary strainers with duplex stainless steel, which ts stronger and more durable than conventional stainless steel,will reduce the frequency of equipment replacement and the use of reinforcement materials,thereby reducing costs.

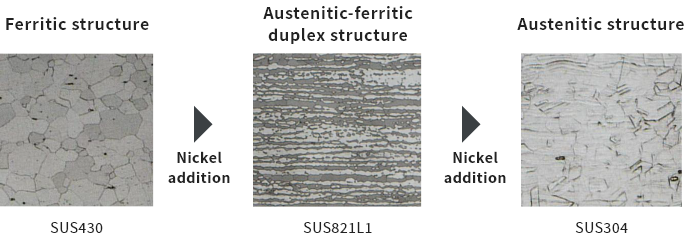

What is duplex stainless steel ?

Duplex steel is different from double-layer steel. Duplex stainless steel has advantages of both austenitic and ferritic structure.

Duplex stainless steel is made by increasing the Cr content and decreasing the Ni content.

Solves strength problem of SUS304・SUS316L wire mesh strainer

Duplex stainless steels have twice the strength and higher hardness properties than conventional stainless steels

Excellent resistance to pitting corrosion and stress corrosion cracking

Duplex stainless steels have excellent resistance to pitting corrosion and stress corrosion cracking in a chloride environment

Excellent buffing and polishing properties

Compared to conventional stainless steel, buffing is easier and surface luster is more easily achieved.

Less thermal expansion and contraction than SUS304

Low coefficient of linear expansion prevents expansion, contraction, and thermal deformation due to heating and cooling.

Uses much smaller amounts of Ni and Mo.

Due to its low content of rare materials, this material is not easily affected by price fluctuations and more environmentally friendly than conventional stainless steels.

Prevents breakage and reduces replacement frequency

Magnetic properties enable detection of foreign objects in the event of breakage.

| Drilling Method |

Hole size (mm) |

Thickness (mm) |

pitch (mm) |

Max. Open area |

Mesh (equivalent) |

Max.Sheet Size(mm) |

|---|---|---|---|---|---|---|

Laser |

φ0.035 | 0.5t | 3.5% | #400 | 900×1800 | |

| φ0.045 | 5.0% | #300 | ||||

| φ0.075 | 6.5% | #200 | ||||

| φ0.110 | 10.0% | #150 | ||||

| φ0.155 | 14.0% | #100 | ||||

| φ0.200 | 17.0% | #80 | ||||

| φ0.270 | 19.0% | #60 | ||||

| φ0.320 | 22.0% | #50 | ||||

| φ0.410 | 22.0% | #40 | ||||

| φ0.560 | 25.0% | #30 | ||||

Perforating |

φ0.700 | P1.5 | 19.7% | #24 | 500×500 | |

| φ0.800 | P1.6 | 22.7% | #24 | |||

| φ0.900 | P1.8 | 22.7% | #20 | |||

| φ1.000 | P2 | 22.7% | #18 |

| Drilling Method |

Hole size (mm) |

Thickness (mm) |

pitch (mm) |

Max. Open area |

Mesh (equivalent) |

Max.Sheet Size(mm) |

|---|---|---|---|---|---|---|

Laser |

φ0.410 | 0.8t | 22.0% | #40 | 900×1800 | |

| φ0.560 | 25.0% | #30 | ||||

Perforating |

φ0.800 | 22.7% | #24 | 500×500 | ||

| φ0.900 | P1.6 | 32.6% | #20 | |||

| φ1.000 | P1.5 | 40.3% | #18 |

※The pattern of Laser screen is Random Straight

※The pattern of Perforated metal is 60 degree staggered.

| classification | Cr | Ni | Mo | Mn | N | Rare metal*1 |

PREN*2 |

|---|---|---|---|---|---|---|---|

| ①SUS821L1 (NSSC 2120®) |

21 | 2 | - | 3 | 0.17 | 23 | 25 |

| ②SUS329J1 equivalent (NSSC®2351) |

23 | 5 | 1 | 1 | 0.17 | 29 | 30 |

| SUS304 | 18 | 8 | - | 1 | 0.04 | 26 | 19 |

| SUS316L | 18 | 12 | 2.5 | 1 | 0.02 | 32.5 | 26 |

●Compared to conventional stainless steel,Duplex Stainless Steel has a higher Cr,lower Ni,Lower Mo,higher N.

It is an eco-friendly material with low content of rare metals.

●NSSC 2110® and NSSC 2351® have a higher PREN than SUS 304 and SUS 316L,respectively.

*1 Sum total of rare metal=Cr%+Ni%+Mo%

*2 PREN=Cr%+3.3×Mo%+16×N%

| classification | 0.2%Yield Strength (N/㎟) |

Tensil Strength (N/㎟) |

Elongation (%) |

Hardness HV |

|---|---|---|---|---|

| ①SUS821L1 (NSSC 2120®) |

570 | 792 | 31 | 256 |

| ②SUS329J1 equivalent (NSSC®2351) |

613 | 830 | 29 | 264 |

| SUS304 | 300 | 654 | 56 | 170 |

| SUS316L | 281 | 561 | 53 | 143 |

●Compared to conventional stainless steel,

| Classification | Density g/㎤ |

Modulus of longitudinal elasticity KN/㎟ |

Specific heat KJ/kg/℃ |

Thermal conductivity w/m/℃ |

Coefficient of linear expansion ×10⁻⁶/℃ |

Magnetic |

|---|---|---|---|---|---|---|

| ①SUS821L1 (NSSC 2120®) |

7.80 | 200 | 0.5 | 16.0 | 13.7 | Yes |

| ②SUS329J1 equivalent (NSSC®2351) |

7.80 | 200 | 0.5 | 15.2 | 13.1 | Yes |

| SUS304 | 7.93 | 193 | 0.5 | 16.3 | 17.3 | No |

| SUS316L | 7.98 | 193 | 0.5 | 16.3 | 16.0 | No |

●Compared to conventional stainless steel,

NSSC's Duplex stainless steel NSSC 2120®(SUS821L1) and NSSC®(Equivalent to SUS329J1) have greatly been improved weldability and can be welded under the same conditions as SUS304.

Please note the following.

| Steel type | Covered arc-welding electrode | TIG welding rod | Flux cored wire electrode |

|---|---|---|---|

| NSSC 2120® | Similar metal (The lean duplex stainless steel) Type 2209 |

Type2209 | Similar metal (The lean duplex stainless steel) Type 2209 |

| NSSC®2351 | Type2209 | Type2209 | Type2209 |

| SUS304 type | Type2209,309LMo,309L |

| SUS316 type | Type2209,309LMo |

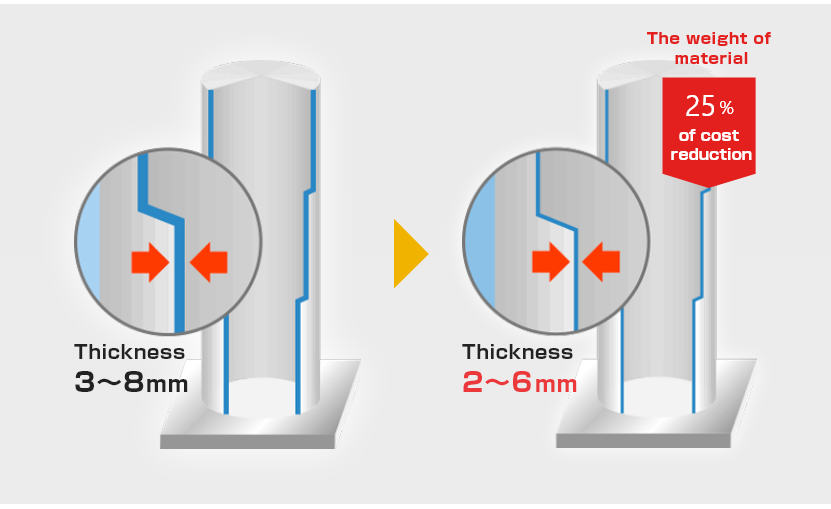

| Thickness | 3~8mm |

| Conventional stainless steel | SUS304 |

| Thickness | 2~6mm |

| Duplex stainless steel | SUS821L1 |

By converting a large tank in a food factory to duplex stainless steel, we were able to reduce the plate thickness from 3 to 8 mm to 2 to 6 mm.

Steel weight has been reduced by 25% to achieve weight savings.

The crane used was downsized to reduce equipment costs.

Mobile sanitary tanks have also been downsized for improved transportability.

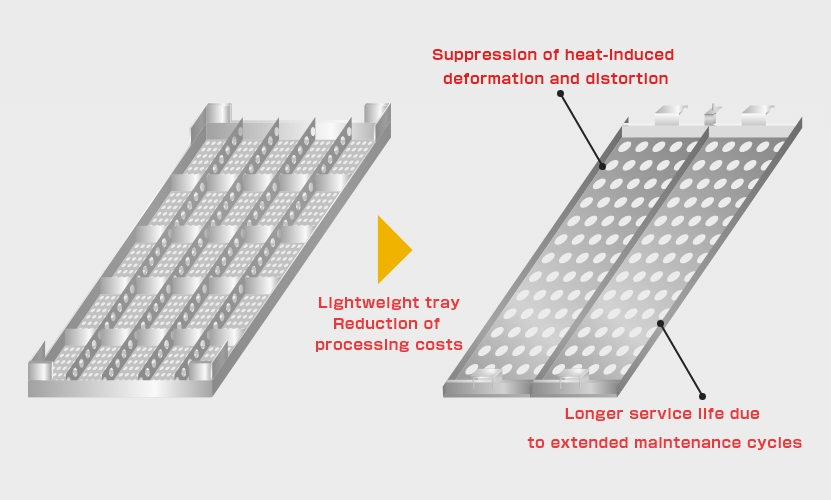

| Conventional stainless steel | SUS304、aluminum resin |

| Duplex stainless steel | SUS821L1 |

Replacing sterilization trays in food plants with duplex stainless steel can increase strength, reduce reinforcement, make trays lighter, and reduce processing costs.

Low thermal expansion makes it resistant to heat-induced deformation and distortion, extending the maintenance cycle and extending service life.

●For more details, please see the PDF file for a larger version.

PDF file (454KB)

<Manufacturer and Distributor>

OKUTANI Ltd.

<Jointly developed company>

NS Stainless Corporation.