Co-development with Toray Plastics Precision Co.,Ltd. (Toray group).(Patented on April, 2017)

CFRTP = Thermoplastic CFRP

Carbon fiber reinforced plastic featuring lightweight and high-strength that uses thermoplastics (which softens when heated and solidifies when cooled) instead of thermoset resin (which hardens when heated and doesn’t return to its original state) is “CFRTP”.

CFRP, which is a lightweight and high-strength material, has been attracting attention for its use in aircraft and high-speed trains, however the mainstream of the existing CFRP is thermosetting CFRP which uses thermosetting resin such as epoxy as the resin based material.

These conventional thermosetting CFRP are, ①Refrigeration equipment is required, ②Long process (Low productivity), ③Post-processing is quite difficult, ④Recycling is difficult and Production costs are high.

On the other hand, CFRTP is relatively inexpensive because of ①storage at room temperature, ②High productivity, ③Easy post-processing, ④Recyclable.

However, in terms of physical properties, thermosetting CFRP is superior to thermoplastic CFRP.

The reason why CFRTP is expected is for automotive lightweight due to enhanced fuel regulations.

Traditionally, the use of CFRTP has been limited to racing cars and ultra-luxury cars, but with mass production and lower costs, there is a growing expectation that it will be used in mass production vehicles.

Material thickness : 0.5mm, 1.0mm and 1.5mm, 3-kinds are available.

Click the brochure below to view in PDF format. PDF file(Article PDF:454KB)

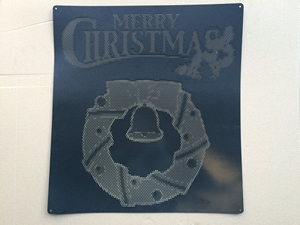

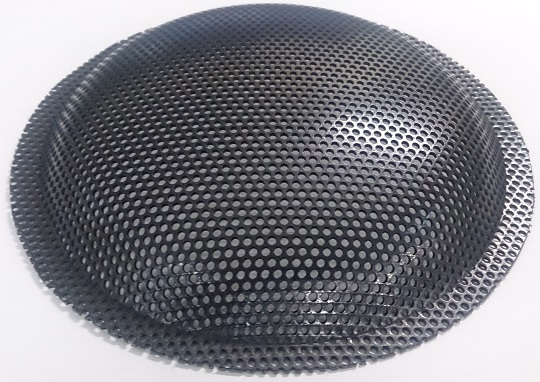

![]() Click the photo to enlarge.※Not to scale.

Click the photo to enlarge.※Not to scale.

|

|

|

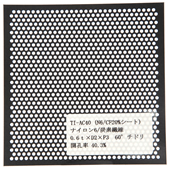

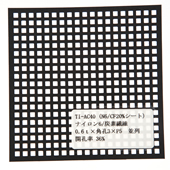

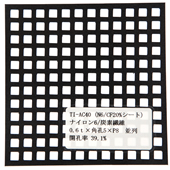

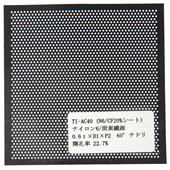

| 0.5t x D3 x Radial array Open area 32.6% | 0.5t x D5 x Radial array Open area 35.4% | 0.5t x D3 x P5 60 deg. Staggered Open area 32.6% |

|

|

|

| 0.5t x D2 x P3 60 deg. Staggered Open area 40.3% | 0.5t x L3 x P5 Straight row Open area 36% | 0.5t x D6 x P9 60 deg. Staggered Open area 40.3% |

|

|

|

| 0.5t x D8 x P10 60 deg. Staggered Open area 58% | 0.5t x L5 x P5 Straight row Open area 39.1% | 0.5t x D1 x P2 60 deg. Staggered Open area 22.7% |

|

|

|

|

|

|

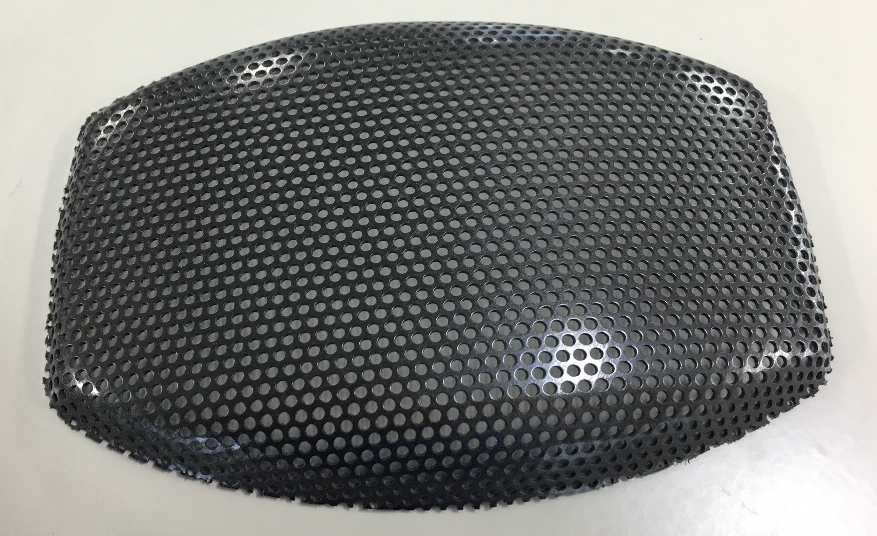

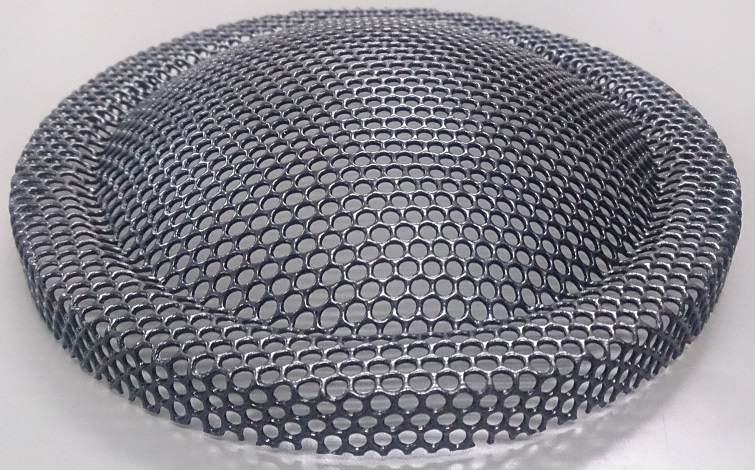

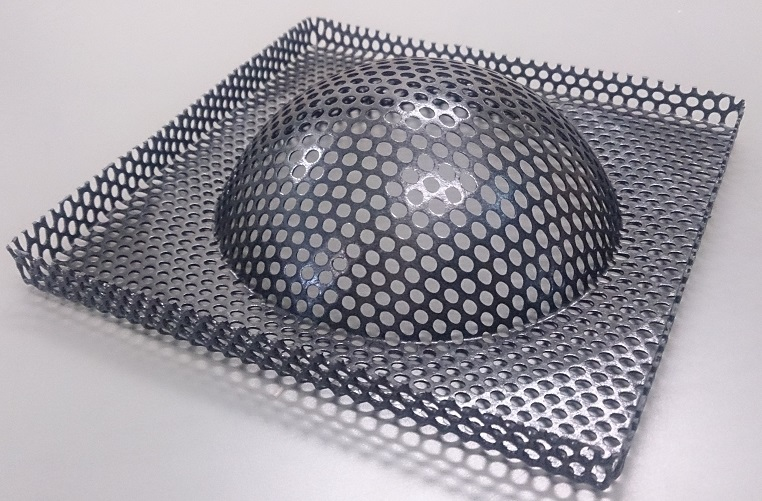

| 3D Perforating | 3D Perforating | Vacuum molding after perforating | Heat-press after perforating |