|

|

|

|

|

|

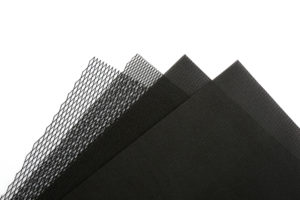

| ・Lightening | ・Formable with existing equipment. |

| ・sliding properties | ・3D-shape |

| ・High open area | ・High vibration damping |

| ・High specific modulus | ・Metal substitutes |

| ・Rust prevention | ・Shortened processing time |

| ・Recyclable | ・Designability |

| ・High acoustics | ・Easy forming |

| ・Heat resistance | ・Heat resistance |

| ・High thermal conductivity | ・Antistatic properties |

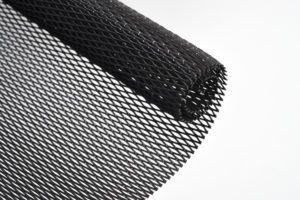

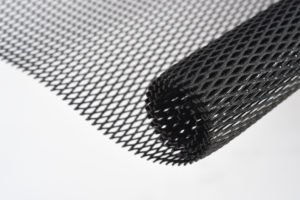

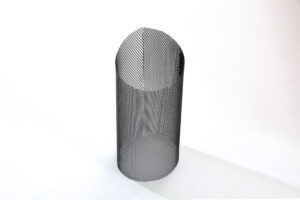

| ・Air filters | ・Housings (Reinforcement) |

| ・Protect covers | ・Speaker covers |

| ・Design materials for interior and exterior |

CFRTP = Thermoplastic CFRP

CFRTP = Thermoplastic CFRP

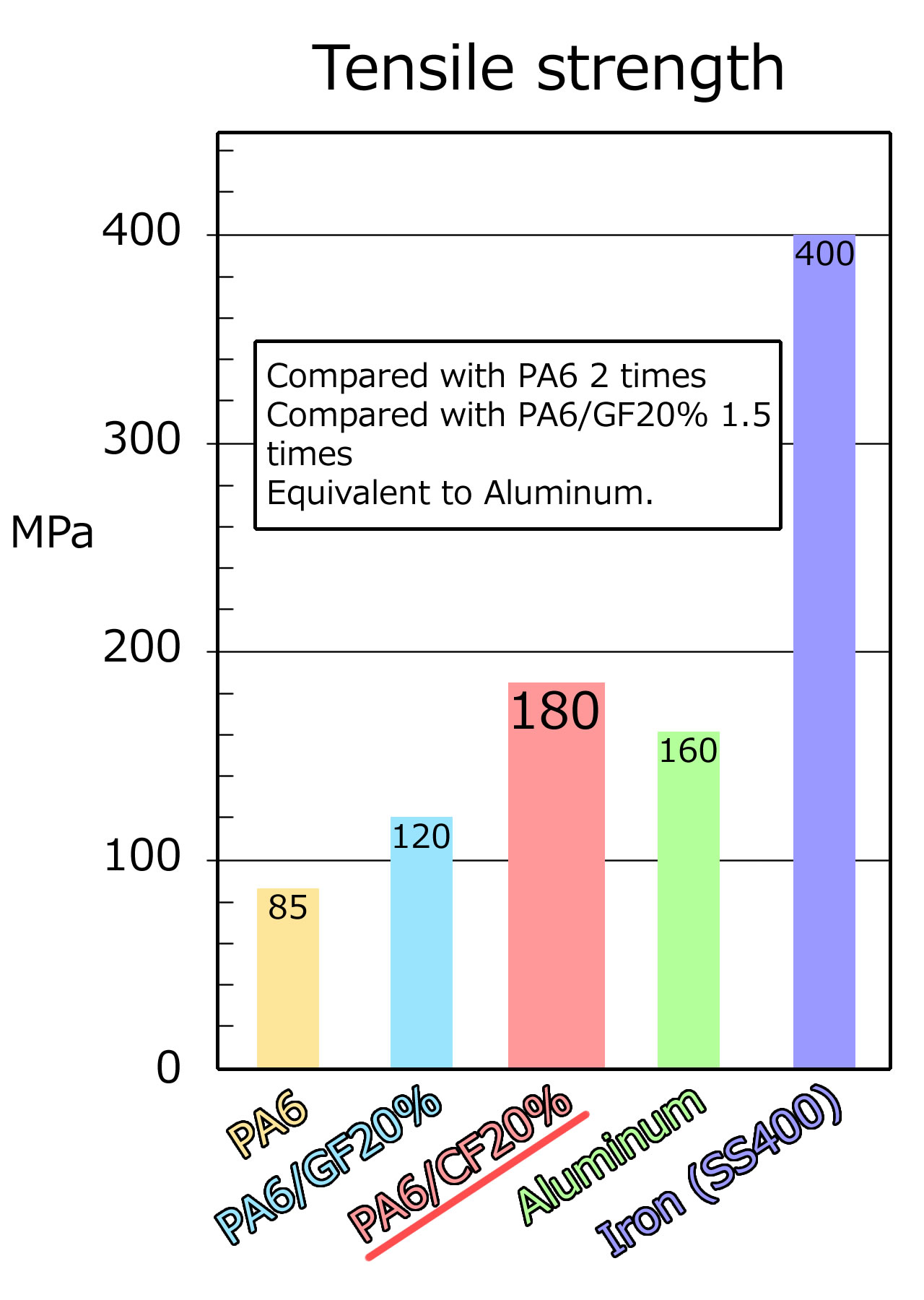

Carbon Fiber Reinforced Plastic (CFRP) featuring lightweight and high-strength that uses thermoplastics (which softens when heated and solidifies when cooled) instead of thermoset resin (which hardens when heated and doesn’t return to its original state) is “CFRTP”.

CFRP, which is a lightweight and high-strength material, has been attracting attention for its use in aircraft and high-speed trains, however the mainstream of the existing CFRP is thermosetting CFRP which uses thermosetting resin such as epoxy as the resin based material.

①Refrigeration equipment is required

②Long process (Low productivity)

③Post-processing is quite difficult

④Recycling is difficult and Production costs are high.

①Storage at room temperature,

② High productivity

③ Easy post-processing

④ Recyclable.

However, in terms of physical properties, thermosetting CFRP is superior to thermoplastic CFRP.

![]() Click the photo to enlarge.Not to scale.

Click the photo to enlarge.Not to scale.

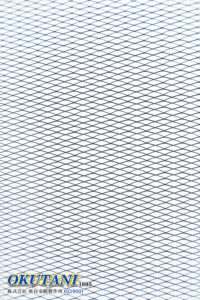

| ④ CF TON 0.35/0.35×3.0/10 | ⑤ CF TON 0.35/0.35×4.6/14 | |||

|

|

|||

| Open area : 70.1% | Product thickness : 0.7 | Open area : 85.2% | Product thickness : 0.7 | |

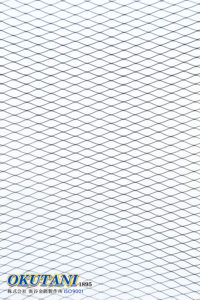

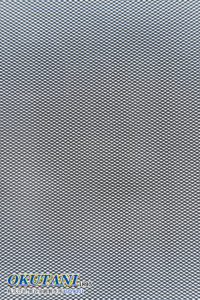

| ⑥ CF TON 0.5/0.5×1.8/3 | ⑦ CF TON 0.35/0.35×1.7/3 | ⑧ CF TON 0.5/0.5×3.5/10 | |||

|

|

|

|||

| Open area : 28.0% | Product thickness : 0.85 | Open area : 59.7% | Product thickness : 1 | Open area : 62.7% | Product thickness : 0.95 |

| ⑨ CF TON 0.5/0.5×4.6/14 | |||

|

|||

| Open area : 74.6% | Product thickness : 1 | ||

| ⑩ CF TON 1.0/1.0×3.4/8 | ⑪ CF TON 1.0/1.0×3.6/10 | ⑫ CF TON 1.0/1.0×4.9/14 | |||

|

|

|

|||

| Open area : 24.0% | Product thickness : 1.95 | Open area : 28.6% | Product thickness : 1.95 | Open area : 48.5% | Product thickness : 2 |

| ⑬ CF TON 1.5/1.5×3.4/8 | ⑭ CF TON 1.5/1.5×4.2/10 | ⑮ CF TON 1.5/1.5×5.2/14 | |||

|

|

|

|||

| Open area : 6.5% | Product thickness : 2.3 | Open area : 11.4% | Product thickness : 2.35 | Open area : 28.8% | Product thickness : 2.95 |

| Expanded CFRTP | Material thicness | Mesh size | Strand | Overall thickness | Percent Open area | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| # | Spec (mm) | SW | LW | Thickness | Width | |||||

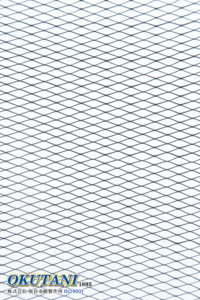

| ① | 0.35/0.35 × 1.2/2 | 0.35T | 1.2 | 2.0 | 0.35 | 0.35 | 0.6 | 26.4% | ||

| ② | 0.35/0.35 × 1.7/3 | 1.7 | 3.0 | 0.35 | 0.35 | 0.65 | 44.4% | |||

| ③ | 0.35/0.35 × 2.8/8 | 2.8 | 8.0 | 0.35 | 0.35 | 0.7 | 68.1% | |||

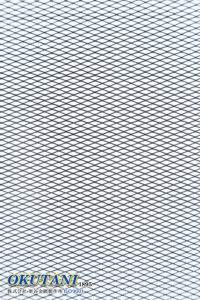

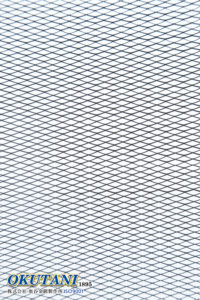

| ④ | 0.35/0.35 × 3.0/10 | 3.0 | 10.0 | 0.35 | 0.35 | 0.7 | 70.1% | |||

| ⑤ | 0.35/0.35 × 4.6/14 | 4.6 | 14.0 | 0.35 | 0.35 | 0.7 | 85.2% | |||

| ⑥ | 0.5/0.5 × 1.8/3 | 0.5T | 1.8 | 3.0 | 0.5 | 0.5 | 0.85 | 28.0% | ||

| ⑦ | 0.5/0.5 × 3.2/8 | 3.2 | 8.0 | 0.5 | 0.5 | 1.0 | 59.7% | |||

| ⑧ | 0.5/0.5 × 3.5/10 | 3.5 | 10.0 | 0.5 | 0.5 | 0.95 | 62.7% | |||

| ⑨ | 0.5/0.5 × 4.6/14 | 4.6 | 14.0 | 0.5 | 0.5 | 1.0 | 74.6% | |||

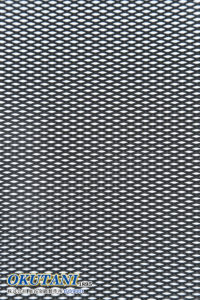

| ⑩ | 1.0/1.0 × 3.4/8 | 1.0T | 3.4 | 8.0 | 1.0 | 1.0 | 1.95 | 24.0% | ||

| ⑪ | 1.0/1.0 × 3.6/10 | 3.6 | 10.0 | 1.0 | 1.0 | 1.95 | 28.6% | |||

| ⑫ | 1.0/1.0 × 4.9/14 | 4.9 | 14.0 | 1.0 | 1.0 | 2.0 | 48.5% | |||

| ⑬ | 1.5/1.5 × 3.4/8 | 1.5T | 3.4 | 8.0 | 1.5 | 1.5 | 2.3 | 6.5% | ||

| ⑭ | 1.5/1.5 × 4.2/10 | 4.2 | 10.0 | 1.5 | 1.5 | 2.35 | 11.4% | |||

| ⑮ | 1.5/1.5 × 5.2/14 | 5.2 | 14.0 | 1.5 | 1.5 | 2.95 | 28.8% | |||