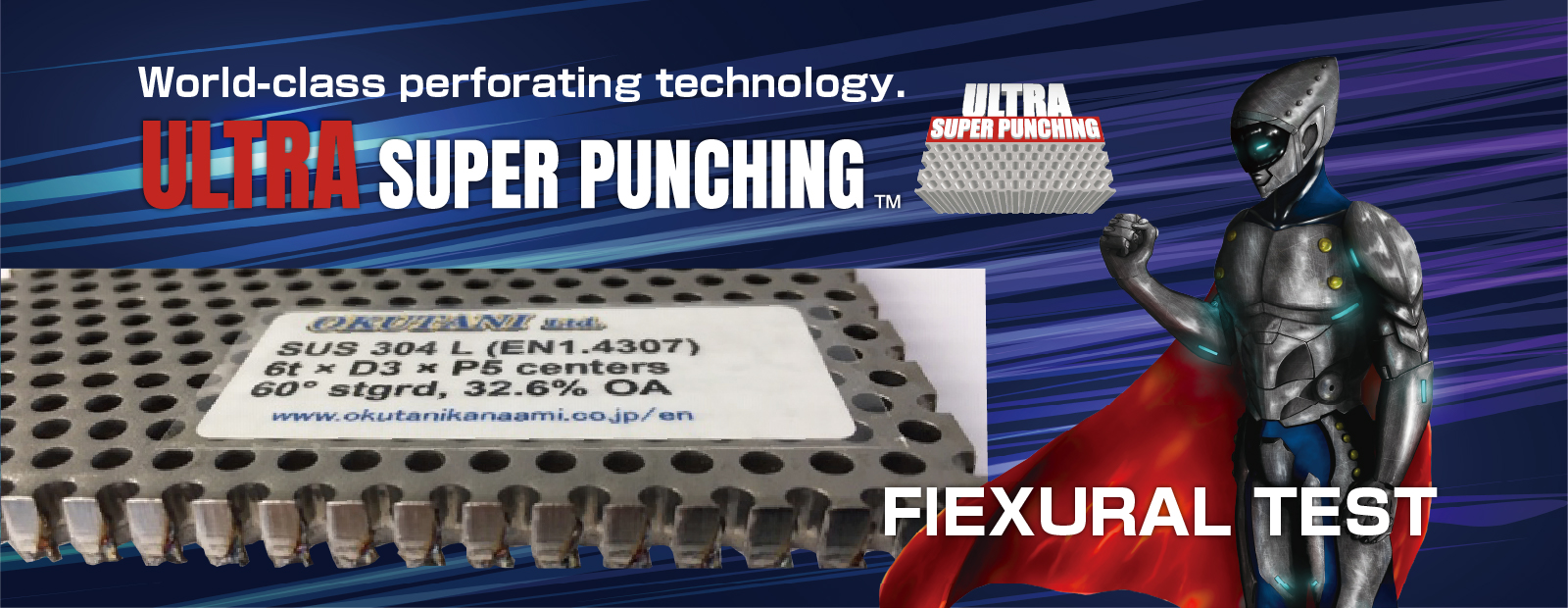

| 1.Purpose | Flexural test for perforated metal. |

|---|---|

| 2.Samples to be tested | ①SUS304 ②-③SUS316L |

| 3.Test Method Picture 1 shows a pre-test appearance and picture 2 shows test piece after the test. |

◎Flexural test

|

| 4.Result | The test results are summarized in the following pictures and table. Picture 1. Test conditions. Picture 2. Test piece after the test. Chart3. Stress-Strain Curve Table 1. Result of flexural test. |

(Table 1)

| Chart | Material | Thickness | Number of test piece |

Dimensions of test piece (found value) |

Environmental temperature |

Ultimate Strength (N) |

Nominal maximum stress |

||

|---|---|---|---|---|---|---|---|---|---|

| width | thickness | ||||||||

| (mm) | (mm) | ||||||||

| Ⓒ | ① | SUS304 | 3.0 | ① | 39.95 | 2.92 | RT (23℃) |

3399 | 959 |

| ② | SUS316L | 3.0 | ② | 40.03 | 2.84 | 1812 | 836 | ||

| ③ | SUS316L | 6.0 | ③ | 40.02 | 5.84 | 15876 | 1099 | ||

| Number of equipment for ①&② : E2-020 # of equipment for ③ : E2-018 | |||||||||

| Remarks | Testing speed : 1mm/min Room temperature : 23℃± 5℃ Nominal maximum stress = 3PL/2bh2 P:Max. test force L:Span 40mm b:Width b´=b-3x5(hole φ 3 pitch 5) h:thickness |

||||||||